The wrong choice of materials in uniforms wastes tons of unsustainable clothing. So, a new challenge arises to the textile industry: how to make business eco-friendly?

A large airline has about 20,000 crew members wearing an average of 20 garments/accessories each, from shirts to badges, from bags to shoes. The wrong choice of materials wastes 20 tons of unsustainable clothing. Furthermore, if we consider staff rotations between 5 and 10%, the damage can be even worse.

According to the Waste and Resources Action Programme (WRAP), only 9% of corporate uniforms today are sustainable. Due to the composite nature of uniforms, including blended fabrics and plastic buttons, recycling uniforms is not an easy task and requires specialized care.

SKYPRO is the only Portuguese strategic partner in developing eco-uniforms, eco-shoes and uniform management solutions to reduce the carbon footprint for the aviation industry.

Our mission is to continuously care for the crew’s health and wellbeing while improving the efficiency of airlines. That includes helping them achieve their increasingly ambitious carbon footprint targets in five ways:

1. USE OF SUSTAINABLE FABRICS AND MATERIALS IN UNIFORMS

In the uniforms industry, the material of most jacket linings is non-biodegradable synthetic polyester; for buttons is virgin plastic, for other garments can be even worse. Although leather is a food industry production, the tanning process includes several stages and chemicals, resulting in the water supply if not carefully monitored.

To help reduce the impact of uniforms on the environment, SKYPRO can produce more sustainable materials using several alternatives.

For example, we can manufacture shoes and accessories made from Piñatex® as an alternative to leather: a sustainably sourced material made from the leaves of the pineapple plant, which are traditionally discarded or burned in the food industry. It is strong, lightweight, breathable, and pliable, and inspired by the natural surface of full-grained leather.

SKYPRO uses other alternative materials :

- Recycled hemp or cotton fiber buttons instead of plastic;

- Ocean-recycled rubber soles;

- Post-consumer recycled polyester linings;

- Biodegradable fibers.

2. CERTIFIED TOXIN-FREE UNIFORMS TO PRESERVE CREW’S HEALTH

Many fabrics and leathers used in mass production contain small quantities of toxic substances which worn daily could affect human health. These include chromium, chlorophenols, formaldehyde and could build up to long-term effects on crew and the environment.

All SKYPRO fabrics are Oeko-Tex® Standard 100% certified, meaning every thread, button and other accessories pass through tests for harmful substances and that the garmend is harmless in human ecological terms.

3. UNIFORMS MADE IN PORTUGAL WITH ECO-RESPONSIBLE SUPPLIERS

We prefer working with suppliers who care for their carbon footprint.

For example, our fabric supplier uses recyclable, carbon-friendly, and biodegradable materials to consume almost all of their energy through solar panels and reuse over 50% of their water resources. They also reuse the scraps from production to develop the textiles for one of their sister brands, contributing to a circular economy.

Furthermore, although most of our clients are from North Europe, Middle East, and North Africa, our production and supply chain are from Portugal. That ensures we can be agile to verify the quality of our products ourselves regularly and reduce the carbon footprint of our shipments.

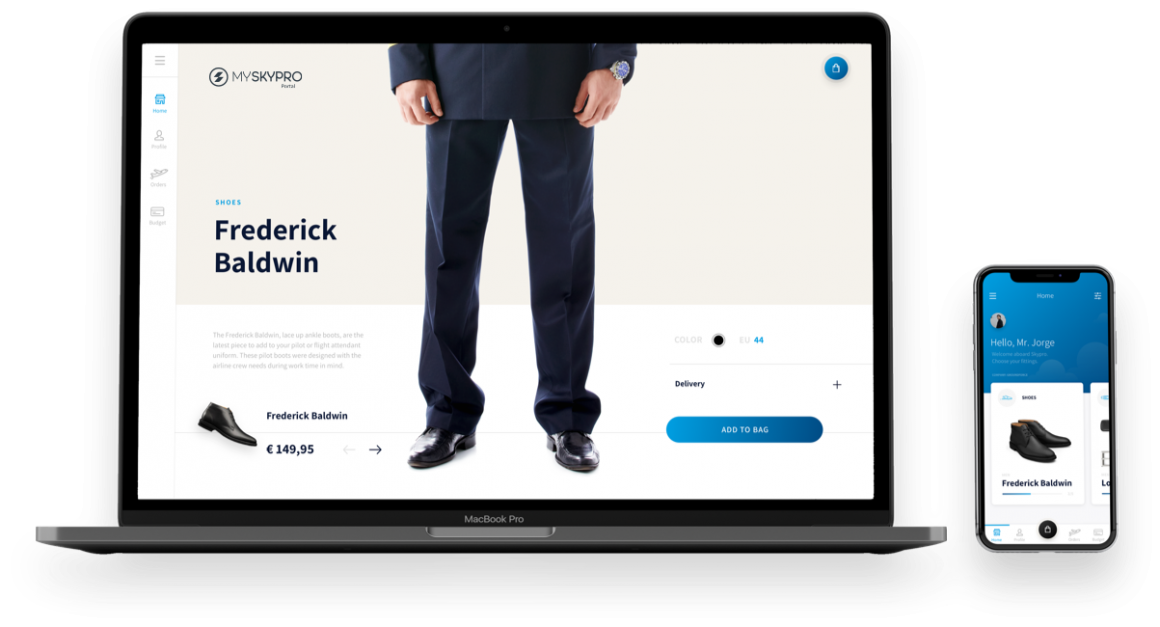

4. REDUCTION IN OVERSTOCK AND WASTE THROUGH MYSKYPRO PORTAL

mySkypro Portal is the industry’s first end-to-end Uniform Management System and represents the digital revolution of uniform management. Amongst several benefits, the Portal allows seamless uniform order forecasting thanks to our smart algorithm. It recognizes patterns in crew ordering behavior and matches it with stock levels and production to trigger order notifications exactly when needed.

Consequently, it saves space in warehouses, decreasing stock levels and minimizing waste and pollution. Going sustainable doesn’t always have to be more expensive and can help you realize cost savings.

5. UNIFORM RECYCLING CAPABILITIES

Several tons of old clothing are discarded into landfills every year and the composite nature of blended fibers makes reprocessing and recycling a challenge. SKYPRO can partner with third parties who have identified sustainable solutions to either recycle or upcycle disposed garments.

Feel free to contact us at sales@wearskypro.com if you would like SKYPRO to evaluate your current uniforms for free and learn how our company can help you reach your sustainability targets.